Click to enlarge

Ceramic firing and pressing furnace

e.ON 250 neo

Ceramic firing and pressing furnace e.ON 250 neo and ceramic furnace e.ON 200 neo combine a range of technological innovations to meet the requirements of today's ceramic materials.

- High definition colour touch screen 7″.

- Detection and display of malfunctions.

- Thermal inertia mastered, no difference between muffle temperature and ceramic wotk due to fibered refractories.

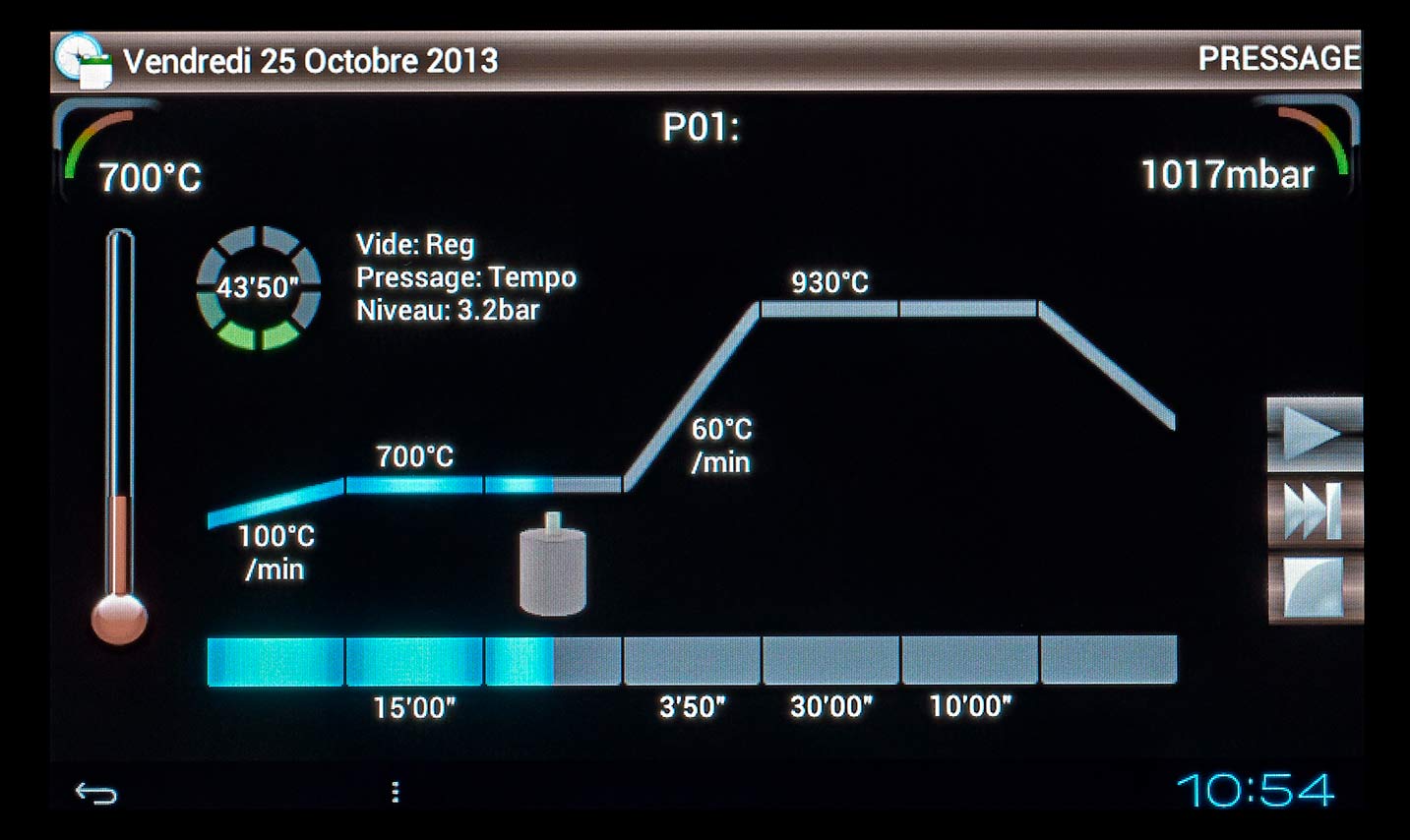

- Pneumatic injection (realibility).

- Triple body compression chamber (regulation).

- Three possible pressing modes: fixed, timed or clocked (for disilicates).

- Injection possible of any type of ceramic.

- Multi-point injection.

Specifications

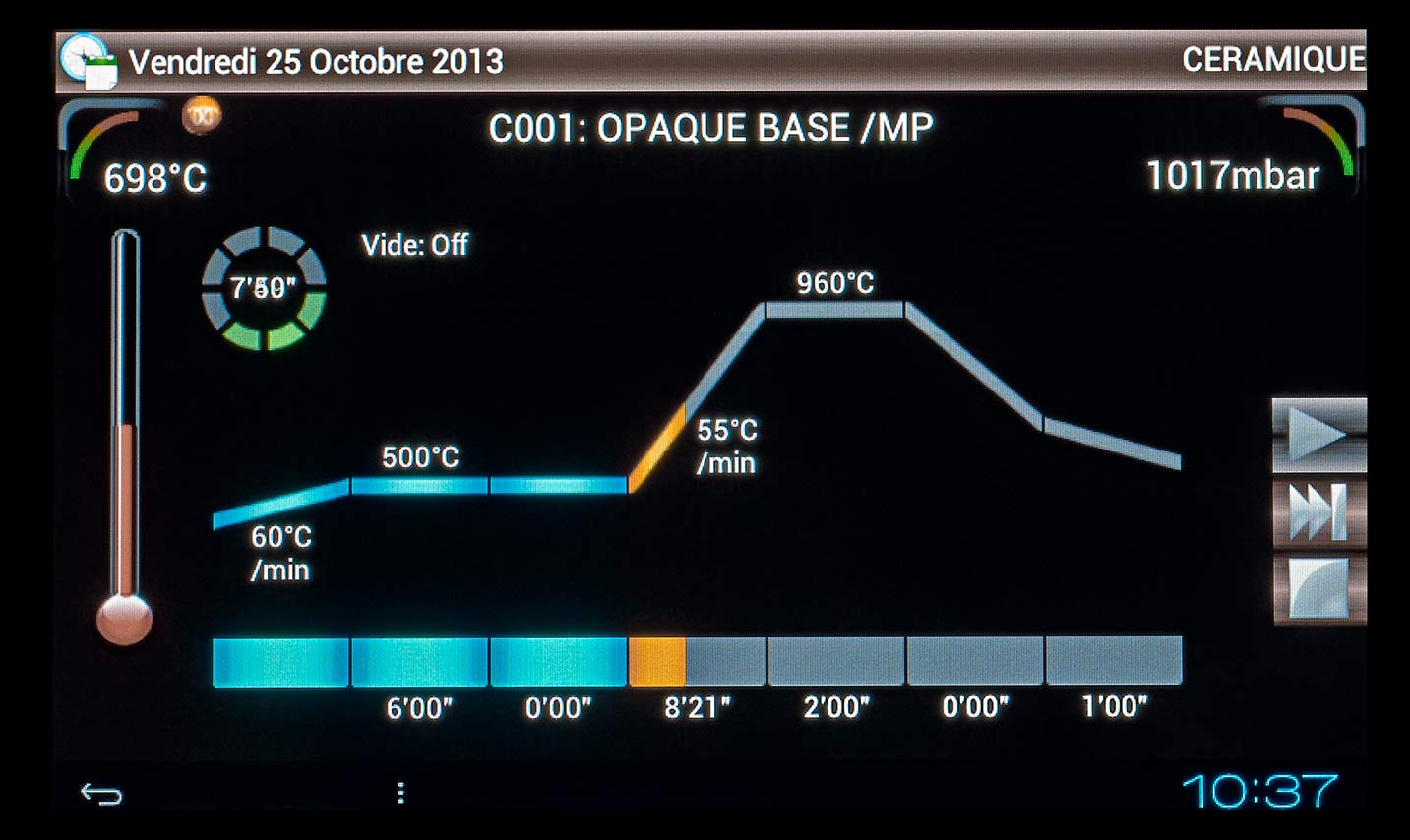

- 100 ceramic firing programmes + 100 corresponding favorite programmes

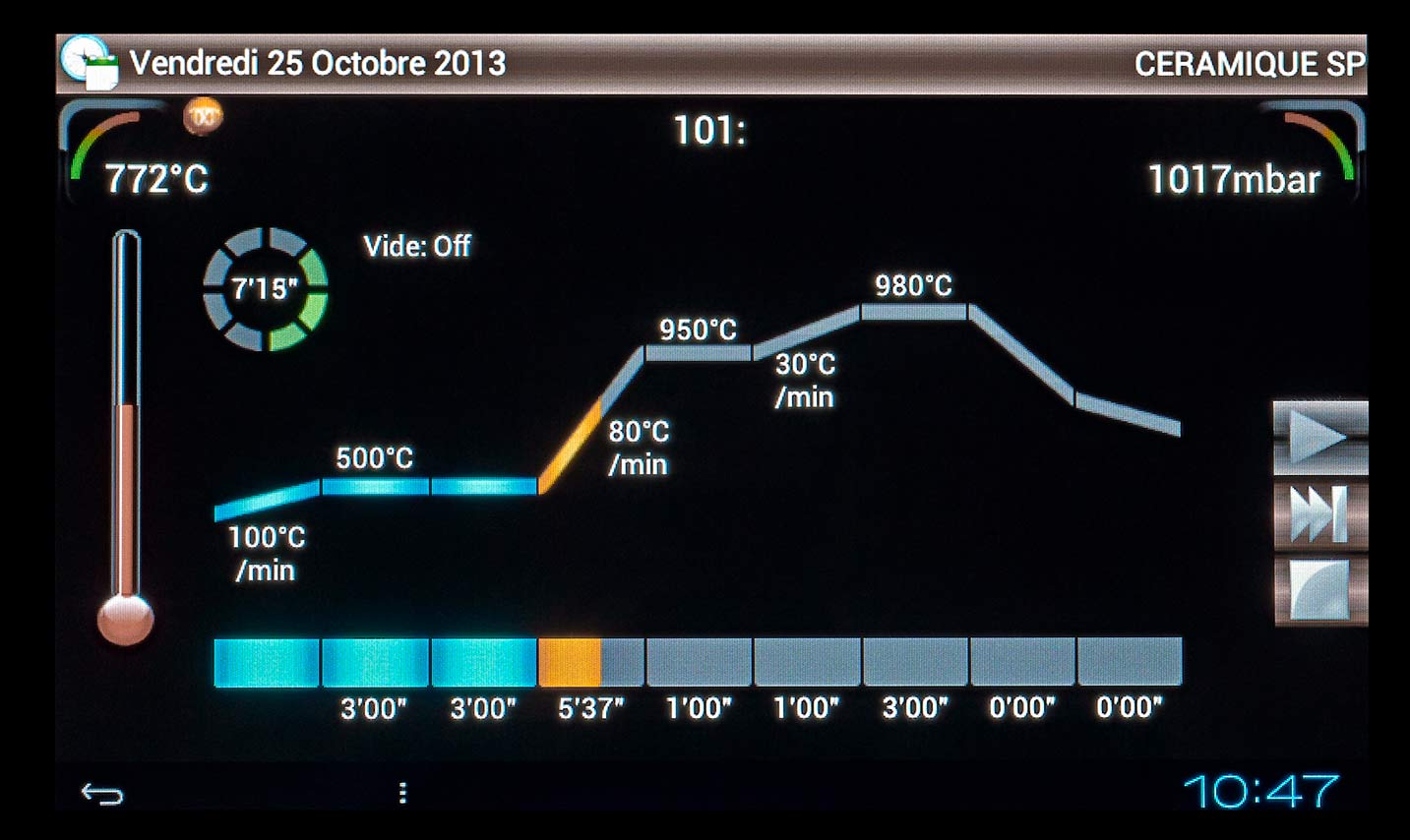

- 100 special ceramic firing programmes (SP) + 100 corresponding favorite programmes

- 50 pressing programmes + 50 corresponding favorite programmes

- Control and monitoring of firing or pressing cycles by dual display color graph

- Automatic calibration program

- Possible custom calibration for each individual program

- Data transfer and storage via USB stick

- 6 display languages: French, English, German, Italian, Spanish, Russian

- External dimensions (height / width / depth): 719 x 320 x 360 mm

- Weight: 27 Kg

- Supply voltage: 230 V (50/60 Hz)

- Maximum power consumption: 1850 W